News Items - International Association of Packaging Research Institutes

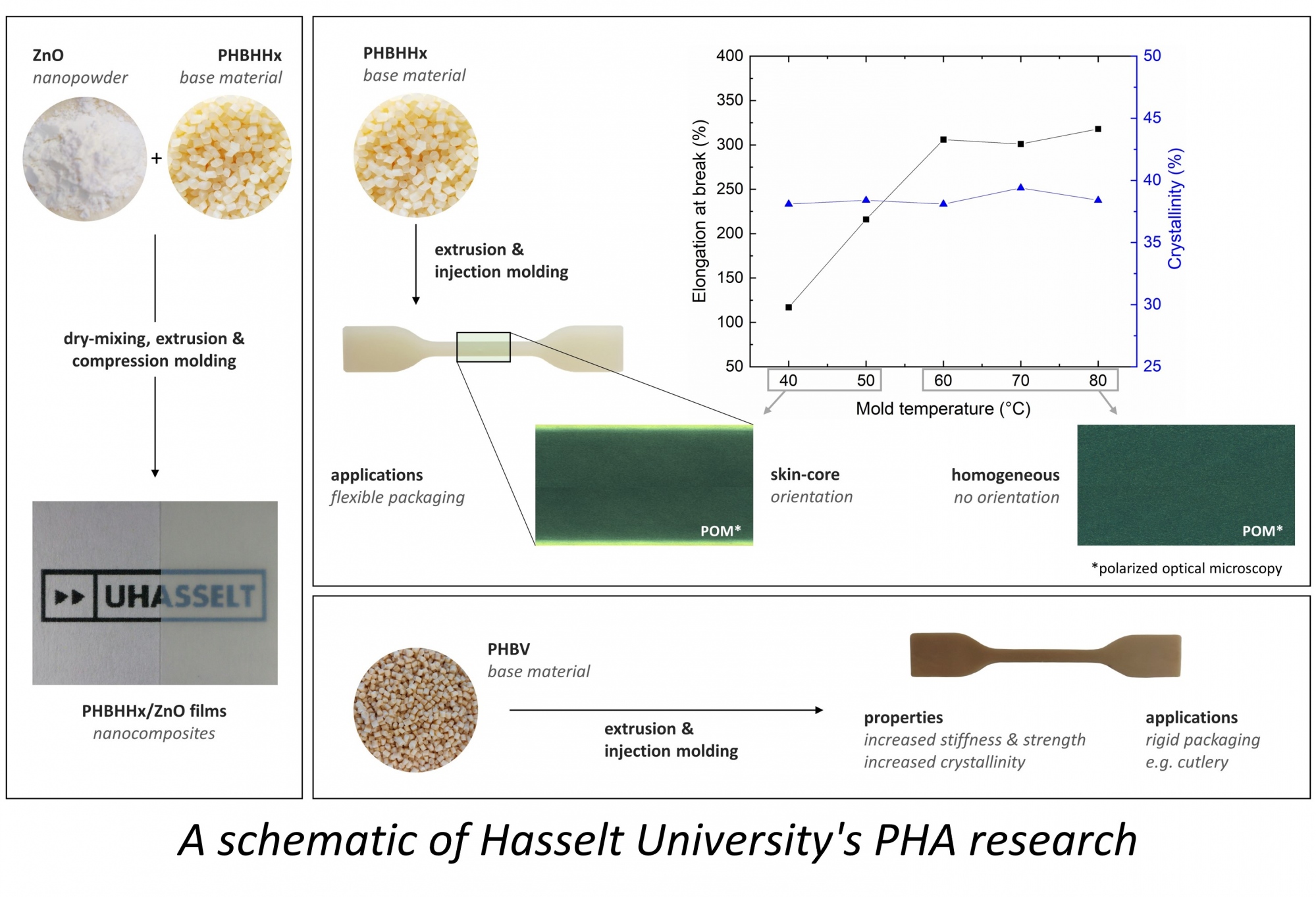

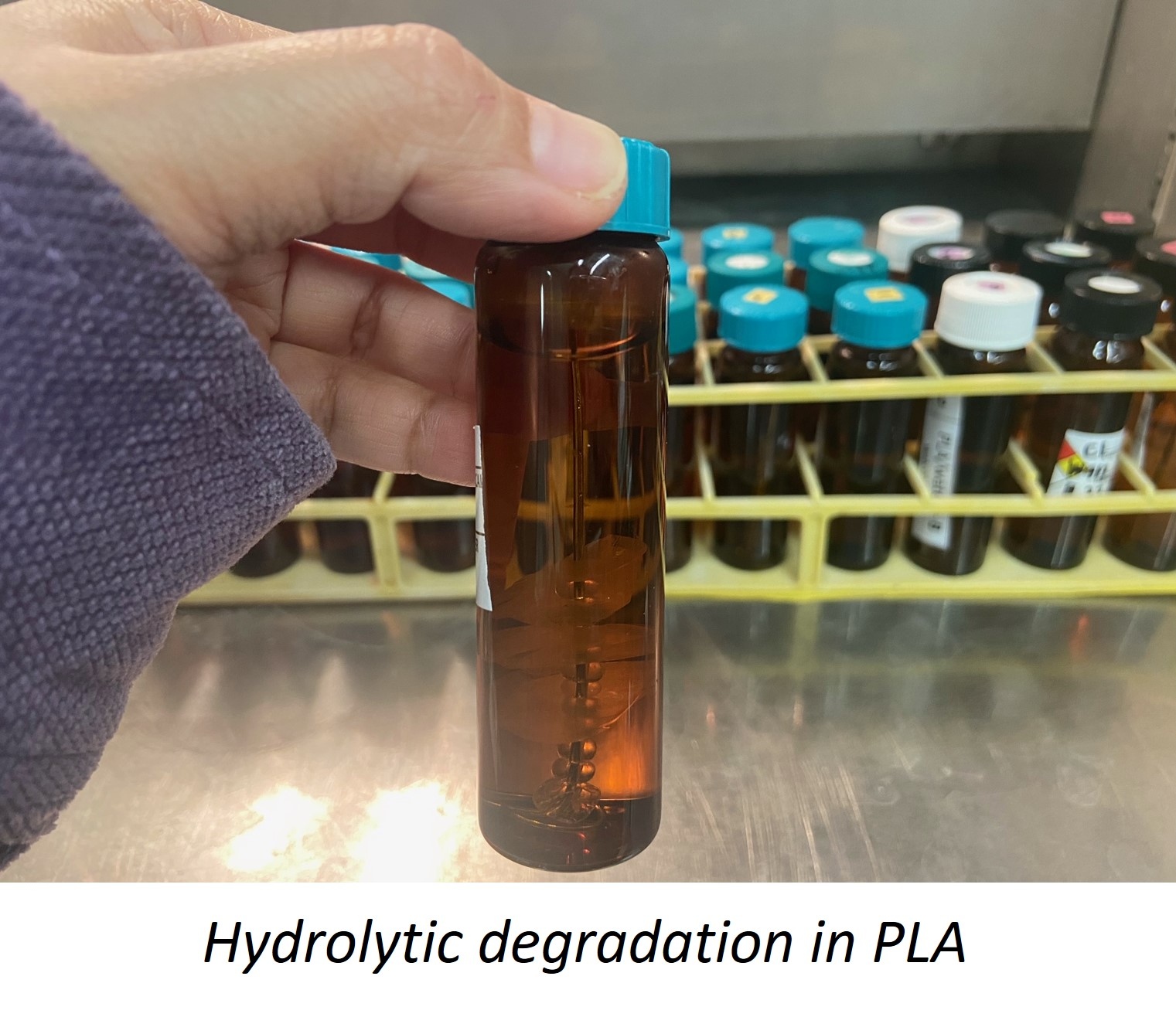

| Crystallized thinking in biopolymer research As IAPRI members prepare for another Conference, we examine the directions being taken by research into biobased polymers, notably PLA and PHA. Several papers from last year’s IAPRI Conference made it clear that research into key biopolymers such as polyhydroxyalkanoates (PHAs) and polylactide (PLA) has long since moved beyond generic analysis. Instead, it is focused on ever-finer distinctions within what can be defined as a single polymer, how these biopolymers behave in combination with other materials and how properties can be optimized in manufacture. So, for example, Chris Vanheusden of Hasselt University’s Materials & Packaging Research & Services (MPR&S) research group in Belgium began his 2021 presentation by stating that, of the various copolymers in the PHA family - including PHB, PHBV, P3HB4HB and PHBHHx - the latter is “the most promising”.  PHB, on the other hand, is relatively “stiff and brittle, with a narrow processing window and high crystalline content”, he explained. “But copolymers such as PHBHHx have broader processing windows, higher ductility and suitable barrier properties for food packaging.” Nonetheless, there had been little research into these materials’ melt processing and induced relationships between structure and properties, he reported.  Another very active research group, this time at Michigan State University’s (MSU’s) School of Packaging, has often returned to PLA as a subject of study. Regarding the choice of material, Rafael Auras, who leads this biopolymer research group, characterizes PLA as “still a relatively new polymer”, but at the same time “an old friend”. “Currently, our research portfolio comprises more than 50% PLA-related projects and other polymers such as PBAT, PET and thermoplastic starch (TPS).” Another very active research group, this time at Michigan State University’s (MSU’s) School of Packaging, has often returned to PLA as a subject of study. Regarding the choice of material, Rafael Auras, who leads this biopolymer research group, characterizes PLA as “still a relatively new polymer”, but at the same time “an old friend”. “Currently, our research portfolio comprises more than 50% PLA-related projects and other polymers such as PBAT, PET and thermoplastic starch (TPS).”The MSU research group is continuously working on improving the structures of PLA and their overall performance. “This development work can provide insights into the biodegradation of PLA, aiming both to tailor stability and biodegradability and expand the commercial use of PLA,” says Auras. Nanocomposites While last year’s Hasselt University paper was concerned with PHBHHx alone, research has taken a rather different direction since then, and preliminary results will be presented at this year’s IAPRI World Conference. “Our ongoing research includes the development of PHBHHx/zinc oxide nanocomposite films and the study of their structure-property relationships, with enhanced properties for packaging applications,” he tells IAPRI. Meanwhile, the aims of his 2021 research were the optimization of PHBHHx melt processing, targeting improved mechanical properties, and an understanding of the correlation between these properties and process-induced microstructure, including crystallinity. Processing temperatures of between 145degC and 160degC were tested on a lab-scale twin-screw extruder, together with the other parameters of injection mold temperature, screw speed and cooling times. The responses measured were: tensile strength, elongation at break and Young’s modulus.  “High mold temperatures result in higher elongation at break,” said Vanheusden. “The mold temperature has a strong influence on Young’s Modulus, too.” “High mold temperatures result in higher elongation at break,” said Vanheusden. “The mold temperature has a strong influence on Young’s Modulus, too.”The tests showed that a relatively low processing temperature of 145degC and relatively high mold temperature of 80degC produced optimum outcomes. Screw speeds were kept at 50rpm and cooling time in the mold at 60 seconds. “Elongation at break was in line with PP and LDPE, and outperformed PHB and PLA,” he reported. “For tensile strength and Young’s Modulus, PHBHHx is most in line with LDPE.” Filling further gaps Follow-up research showed that processing at a low mold temperature of 40degC induces skin formation with increased crystalline molecular orientation. “Processing at the higher mold temperature of 80degC reduces skin formation, while developing a more homogeneous microstructure, with increased crystal size,” he says. “This microstructure leads to increased elongation at break values, while maintaining sufficient strength and stiffness.” He adds that this is also likely to be related to lower residual stress in the polymer chains, induced by slower cooling rates of the melt during molding. For comparison, the Hasselt University team also carried out similar research on low valerate PHBV. This suggested that the tensile strength and Young’s modulus of PHBV can be increased under a critical set of processing conditions in parallel with higher crystallinity. “However, the elongation at break of PHBV remains very low,” Vanheusden cautions. “Low valerate PHBV therefore shows potential for use in more rigid applications like cutlery, while PHBHHx shows promise for use in more flexible packaging applications.” Hydrolysis in action Crystallization can be a key issue with PLA, too. MSU’s Wanwarang Limsukon last year presented a paper exploring the hydrolytic degradation of this biopolymer, and how this was related to crystallization behavior.  As she explained in her 2021 paper: “One of the limitations for PLA in long shelf-life and high-temperature applications is that it’s subject to hydrolytic degradation, especially at high humidities, leading to a deterioration of the structure.” As she explained in her 2021 paper: “One of the limitations for PLA in long shelf-life and high-temperature applications is that it’s subject to hydrolytic degradation, especially at high humidities, leading to a deterioration of the structure.”Crystallinity, which is one of the key determinants affecting hydrolytic degradation in PLA, can be influenced by the stereochemical structure. Commercially available PLA typically contains between 1-10% of the D-lactide isomer, the remainder consisting of L-lactide. “This can affect the crystallinity and also the thermal properties of the material,” she pointed out. Limsukon went on to outline the three-phase model of PLA, from the mobile amorphous fraction (MAF), to the rigid amorphous fraction (RAF), and finally the crystalline fraction (CF). The objective of the research, she said, was to investigate this three-phase structure during hydrolytic degradation and to establish the effect of RAF on the rate of degradation. Two different grades of PLA were used, with contrasting levels of L-lactide content, and two different crystallization methods were employed. The 99%-L-lactide (PLAH) and 96%-L-lactide (PLAL) grades were processed by cast film extrusion, and then subjected to cold crystallization and melt-stretch crystallization, after which the MAF and RAF ratios were calculated. “In the final part of this experiment, we calculated the rate of hydrolysis in each sample,” said Limsukon. Patterns of diffusion “During hydrolysis, PLAH has a higher attainable crystallinity, decreasing the effective water diffusion into the film matrix,” she explained. “The increased tortuous pathway of diffusion in amorphous PLA slows down hydrolysis.” The process was faster in the PLAL variant, she said, due to the higher D-lactide content, which can interrupt the crystallization process and increase the RAF function. “There are still data gaps,” she concluded during the 2021 Conference. “We need more qualitative analysis of RAF for the slower hydrolysis in amorphous PLA and the faster hydrolysis in cold-crystallized PLA with higher amounts of L-lactide.” Like the Hasselt University group, the MSU team has continued to pursue its research. “After the Conference, we confirmed that PLA with a higher crystallinity fraction has a slow hydrolysis rate due to limited water diffusion in the crystalline structure,” Limsukon tells IAPRI. “Conversely, the initial amount of RAF could speed up the hydrolysis affected by the higher water diffusion, and make more hydrophilic end groups at the early state of this phase.” Further stability against hydrolysis is provided by the modified structure of the nano-confined PLA crystals from the melt-stretch method, which limits the diffusion of water molecules into the PLA film, she adds. Canadian layers Nanocomposites are not the only route to combining biopolymers with other materials for improved performance. Last year’s Conference also heard from Joseph Higginson from Lakehead University in Thunder Bay, Canada. Higginson worked with supervisor Ehsan Behzadfar, also of Ryerson University, Toronto, on developing PLA/TPS layered films for packaging applications. Explaining how the two substrates complemented each other, Higginson said: “While the hydrophobicity of PLA leads to low water vapor permeability, the crystallinity in the structure of TPS leads to low gas permeability.” Previously, he said, no systematic study relating the properties of PLA/TPS layers to their material and processing parameters had been completed. The coextruded films produced contained glycerol and urea as plasticizers in the starch-based thermoplastic. Different shear rates from the die and multiple TPS blends were experimented with, and these films were then tested for adhesion-strength and layer uniformity. Published: 04/28/22 |