News Items - International Association of Packaging Research Institutes

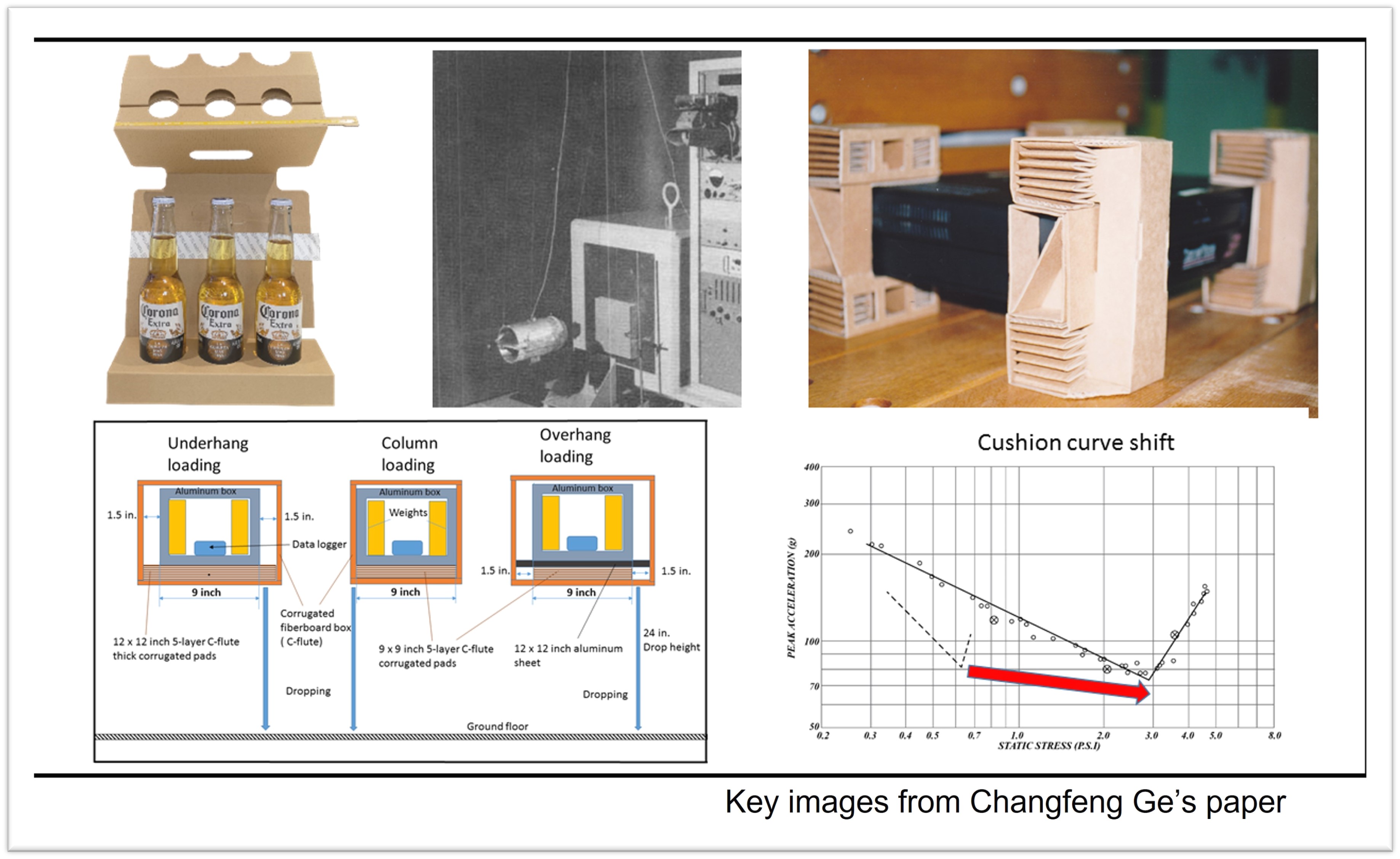

| New departures in transport and distribution It is a paradox that many current options for packaging sustainability reprise technologies which were popular many years ago, faded away in the face of competition from other materials, and have since made a return based on their environmental credentials. Examples might include simplified, ‘recycle-ready’ plastics structures and corrugated board padding for goods in transit. In one of several papers selected for the peer-review stream of IAPRI’s summer Conference, Changfeng Ge of Rochester Institute of Technology (RIT) in the US re-examined studies of corrugated fibreboard used for cushioning. Past and present perspectives  Here, he was able to compare test techniques and results from two very different periods: the 1960s-to-‘70s and current methods. It was clear, as he says, that the testing and data-collection instruments for assessing cushion properties have changed or been improved upon. Here, he was able to compare test techniques and results from two very different periods: the 1960s-to-‘70s and current methods. It was clear, as he says, that the testing and data-collection instruments for assessing cushion properties have changed or been improved upon.Much of the research, despite being sometimes 50 years old – or older, provided valuable insights. For example, one study examined the effects of atmospheric humidity and temperature on cushioning performance. By reviewing past studies looking at crush resistance and cushion curves of different corrugated structures, one objective of Ge’s paper was to provide practical guidance on predicting cushioning performance. There are some specific comparisons. For example, he contrasts the performance of layered and constructive corrugated pads. “The layered corrugated pads with zigzag elements are material- and labour-intensive, but provide the product with more resilient support than constructive corrugated pads,” he concludes. Under the ‘constructive’ category, Ge includes tubular structures. “The tube-based constructive corrugated pads, with the tuck-locking mechanism, offer a cost-effective solution to products, thanks to their combined advantages of low material cost, versatile flute direction and easy assembly,” he adds. As Ge explains, corrugated fibreboard has an orthotropic structure, exhibiting different cushion properties when the flute is aligned vertically or horizontally in relation to the impact direction. A long plateau area on the stress/strain curve is characteristic of layered corrugated pad performance, resulting from widespread interflute buckling. “In addition, the double dipping points and shift-to-the-right tendency of the cushion curves are unique properties of corrugated fibreboard cushioning that cannot be overlooked, and require further investigation,” Ge recommends. “The underhang loading pattern was mainly attributed to these two behaviours.” Alongside the review section, in an updated portion of his report, he maps typical cushion curves for underhang, overhang and column loading patterns. Rather than simply referring to the relevant cushion curve, Ge advises engineers to investigate how samples were impacted over the curve development, as well as the optimum loading pattern for the product in relation to padding. A further recommendation is that future research should focus on those structures which are easy to manufacture with minimum use of materials, and should develop cushion curves and crush strength measurements for those selected configurations. Brute force on film Another peer-review paper selected from the Distribution & Transport Packaging section of the Conference was from Manuel Garcia-Romeu of Safe Load Testing, Spain, looking at the effects of sustained forces in transit on the creep behavior of stretch film, and their impact on unit load stability. “When the stretch film is applied, it constrains the load by applying a force on the load,” he says. “But what happens when the load applies a force on the film?” As Garcia-Romeu makes clear, if the film does not contain the verticality of the load while on the road, “it could become a deadly issue.” His paper details the ways in which loads can be destabilized during road transport as a result of horizontal acceleration during braking, changes in direction, roundabouts and curves. When creep deformation in the pallet stretch film is transferred to a strain-time plot, the resulting curves can be divided into primary, secondary and tertiary regions, he explains. “The primary region is characterized by an initial linear visco-elastic strain with a high but decreasing strain rate,” says Garcia-Romeu. “The secondary region is characterized by a constant strain rate (steady state); and the third region is characterized by a swiftly increasing strain rate and final failure. Thus, when it comes to design purposes, the primary but also the secondary regions are of the highest concern.” By way of background when applying stretch film to a load, he highlights the importance of obtaining - and understanding - the curve plotting force/stress against deformation/strain. Experts in this area know that the film should always be pre-stretched to the Natural Draw - or Stretch - Ratio (NDR) point, in order to optimize the stability behavior of the unit load. The NDR point is defined as a steady-state stretch once the necking phase of the stretch pattern stabilizes. The trials at Safe Load used a 15-micron commercially available stretch film. Testing measured the effects of applying constant force at different levels to film that was pre-stretched to varying degrees. From a practical point of view, Garcia-Romeu’s paper includes a detailed discussion of the relationship between his test findings and load instability. He then goes on to apply the creep test outcomes to a hypothetical example. “The case to study is a two-layer box-loading unit,” he explains. “Each layer is formed by four boxes of 50kg each.” Once the boundary conditions, such as maximum steady acceleration and displacement allowance, have been established, calculations can be applied, and the required pre-stretch and number of windings deduced. So, using this example, and based on the assumption that the film is to be effective beyond 9.8kg of constant force, “the only possible pre-stretch percentage to use is 294%”. He adds the calculation that this would equate to a film consumption of 84g per unit load. But Garcia-Romeu also factors in the different types and capabilities of pallet wrapper; for example, those only allowing a fixed pre-stretch of 175%. “[In this case], the film can only work at 5.8kg of constant force to take care of the creep effect, and the winding will increase from 12 to 18,” he calculates, adding that this would require 180g of film per load, or 114% more than in the optimum case. He ends his conclusion by confirming that the procedure outlined in his paper can help in the design of stretch film wrapping schemes for unit loads, taking into account the steady accelerations experienced in transit. But he adds an important further point. This design step does not avoid the need for validation of the palletized unit load through “well-known static and dynamic testing procedures” laid down in the protocols of companies and standardization organizations. While Changfeng Ge’s paper has already appeared in the pages of the journal Packaging Technology and Science (PTS), others - including Garcia-Romeu’s - were still under review at the time of writing this article, and will be published in a full and finalized version by PTS in the near future. As smooth as silk? But the Distribution & Transport Packaging sessions from the IAPRI Conference demonstrated once again the very high quality of research among members, not just at peer-review level, but all the way through to standard-stream presentations – and some excellent poster presentations, too. Just to cite two examples, the team at ESIReims and METROPACK in France presented posters looking firstly at recording and analysing Europe/China rail transportation, and a second looking specifically at transloading events on the New Silk Road. As the first presentation makes clear, the rail component of the route from China to Europe consists of seven days or more of continuous vibration. A datalogger was used to measure and record unit load oscillations in transit. In addition, a high-speed camera was deployed to measure horizontal deformation at the top of the pallet load as a result of ignition shock on the various legs of the train journey. For the second New Silk Road paper, data recorders allowed researchers to estimate that there were between 20 and 30 breaks to the rail journey. These breaks could involve transloading an entire container, a pallet load or simply hitching wagons to a new engine. An analysis then looks at the various stresses generated by handling equipment at these junctures. Initially, the frequency of vibrations, the accelerations generated and their duration were mapped. “A test protocol was developed in the laboratory to encompass these different breaks of load,” the authors report. They conclude: “In this trip, we have also found long acceleration phenomena. This type of event induces potential problems of load stability. More data must be provided in order to refine this analysis and complete the different results.” If all these papers have anything in common, it is the fact that there is always more data to be gathered, analysed and responded to. Published: 09/29/22 |