News Items - International Association of Packaging Research Institutes

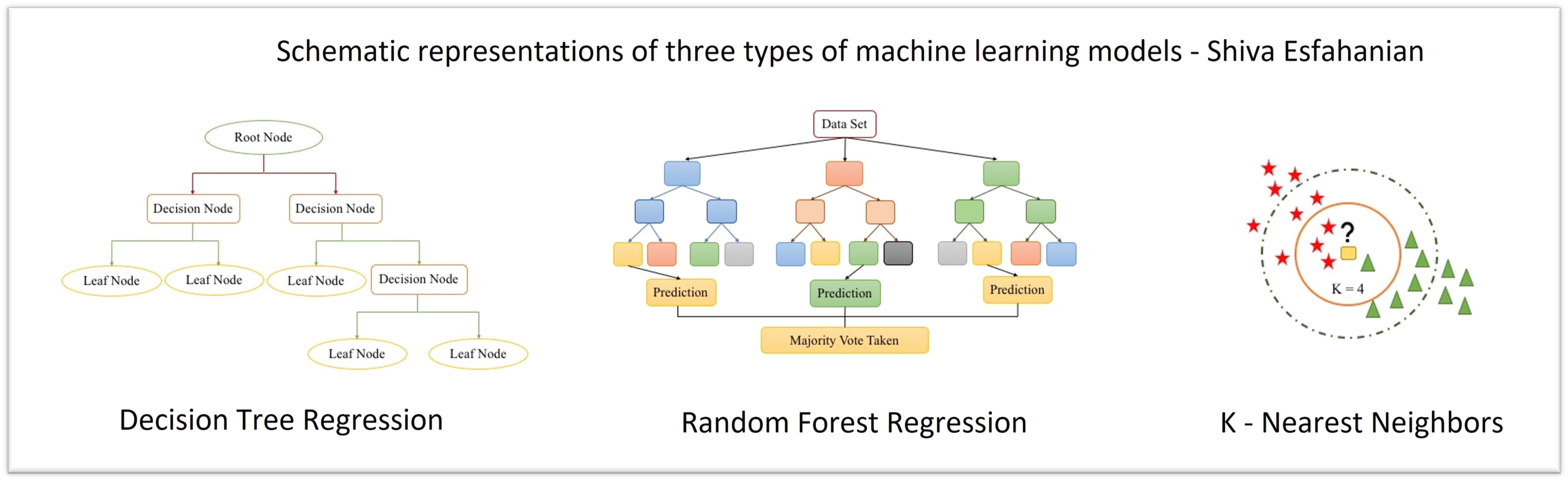

| Lessons in Machine Learning In their IAPRI 2022 Conference paper looking at the compression strength of corrugated packaging, Khadijeh Shirzad and Amin Joodaky of MSU School of Packaging define Machine Learning (ML) as “a subfield of artificial intelligence that develops a mathematical approach to predict complex patterns of sample data”. Anecdotally, packaging-related studies involving ML have seen a significant increase, not least among the papers presented at IAPRI’s June Conference. But which are the research areas where it is currently proving most relevant, and where might it be applied in the future? Packaging researchers at MSU are exploring various roles for ML. We can return to the Shirzad/Joodaky paper later in this article, but turn first to another source within the School of Packaging for an initial overview. Sentiment analysis Euihark Lee co-authored another paper for the Conference, with lead author Shiva Esfahanian, Lanqing Liu and Laura Bix, this study examining ML modelling of patient attention to over-the-counter (OTC) label design. But in a separate paper published earlier this year in Wiley’s Packaging Technology and Science (PTS), looking at sentiment analysis (SA) of customer reviews as a form of evaluation, authors Esfahanian and Lee summarize the principal applications of ML to date. While other disciplines employing ML have included disease discovery and language translation, says the PTS paper, packaging applications have included the design of primary packs such as bottles and the mobilization of SA for various objectives. As the study notes, SA will always be dependent on natural language processing (NLP), and in its own case this allows SA to be applied to opinion mining. Speaking to IAPRI, Lee explains that where artificial intelligence (AI) is already an integral part of a process - in some packaging equipment, for example - ML can be one of the benefits. “Here, it is used a great deal in areas such as optimizing control parameters,” he says. “It is also applied to analyzing images for quality control.” Otherwise, he emphasizes that ML applications in packaging are still at a very early stage, and activity in this area is limited. But there are good reasons why that might change. “For ML to work, you need a lot of data,” he says. “It is important to have data of the right quality and quantity, and I think packaging has both.” In the future, he foresees a time when many of the elements within the packaging design process can be undertaken by ML. “If you were designing a water bottle, for instance, ML could run the data-mining, based on which bottle is the most attractive, the most sustainable, and so on, and provide tools for design guidance,” says Lee. “People currently have to rely on their own experience, but ML can access and analyze any information available on the internet.”  Patient information Regarding the paper on label checking for OTC medicines, patient safety is, of course, of paramount importance with any kind of pharmaceutical product. But because OTC medication is, by definition, self-prescribed, the role played by on-pack warnings and other information is especially critical. But how to evaluate whether such information is effectively conveyed to the patient? Previous studies employed different strategies to focus patients’ attention to the label, such as putting text inside a box, using bold or coloured highlighting. But given the cost and time requirements of using in-person testing of label effectiveness, in this paper, ML is applied to checking and then predicting patient perception of changes to the label. Three different ML algorithms or models are used: decision tree; random forest; and k-nearest neighbors. For each of these models, predicted classification accuracy was shown to be 79%, 92.6% and 91.4% respectively. “The pharmaceutical industry is very wary about changing from in-person testing to ML,” Lee admits. Then again, there would be no need to undergo a wholesale shift from one to the other. “You could use ML to narrow down the in-person testing to, say, two or three tests.” There are other ways of introducing ML in a more considered way, as lead-author on the paper Esfahanian explains to IAPRI. “I collected in-person testing from 60 participants, but it is hard to collect that data, and our goal is to reduce the time required,” she says. “You can’t just stop running tests: you need them. But sometimes, when there’s a change to the label, you have to rerun the entire test. This is the part of the testing process that we’re trying to reduce.” Consumer results can vary from region to region, which is one of the limitations of in-person testing. In time, says Esfahanian, her own results from Michigan could be aligned with others from other parts of the US to allow brand-owners to run potentially more representative label testing – but using ML rather than an in-person approach. Data-mining potential Reductions in test times are also behind Esfahanian’s work on the PTS paper discussed above. In this case, the aim was to analyze online consumer reviews using SA, with a focus on negative sentiments. The paper concludes by claiming: “The evaluation process can be more efficient in comparison to using laboratory tests.” A percentage of failure can also be extrapolated to ensure that the current design’s assurance level is met. In his own paper for the IAPRI 2022 Conference, Thomas Goudsblom of Twente University, the Netherlands, touches on ML applications similar to Lee’s regarding data-mining for future design strategies. His presentation on foresight methods in future-driven packaging design looks at the Bullet Train Model, but concludes that ‘envisioning’ methods could be subject to undue levels of bias. He recommends investigating “how AI, ML and systematic technological assessment can be incorporated into the method and trend research, to possibly reduce the biases”. Researchers would be limited by time, as well as by their own knowledge, he tells IAPRI. “ML could scan a vastly bigger collection of digital data in more domains to find trends in a much shorter time,” he says. “This results in not only more, but also a more ‘fair’ and ‘inclusive’ collection of trends.” As well as identifying trends, ML could contribute to the evaluation stage. “ML could help in making a more structured and thorough evaluation of the trends, considering possible correlations,” he says. Human efforts here would almost certainly be less consistent and much more time-consuming. There are clear challenges and limitations to the scope of ML in these applications, though. “Whereas ML can potentially be very effective in scanning the digital world, humans are very capable of scanning the physical world,” Goudsblom points out, highlighting the role of the observed environment, targeted interviews, co-creation, and so on. But the analysis of online data is by no means the only avenue open to ML. As already referenced, in their own contribution to this summer’s IAPRI Conference, MSU’s Shirzad and Joodaky looked at the effects of a single ventilation hole’s location and geometry on the compression strength of corrugated board boxes. Four ML models were utilised to predict outcomes in the Shirzad/Joodaky paper: multiple linear regression; support vector regression; decision tree regression; and random forest regression. A series of physical tests were carried out, varying the diameter and positioning of the ventilation hole, and this provided the sample data for the ML process. In this case, the random forest regression model once again showed the highest accuracy at 91.26%. Finally, we could indulge in some foresight and envisioning of our own, and predict that in the very near future, the role of ML in a wide range of packaging-related applications will be far more widespread than it is today. Published: 10/28/22 |