News Items - International Association of Packaging Research Institutes

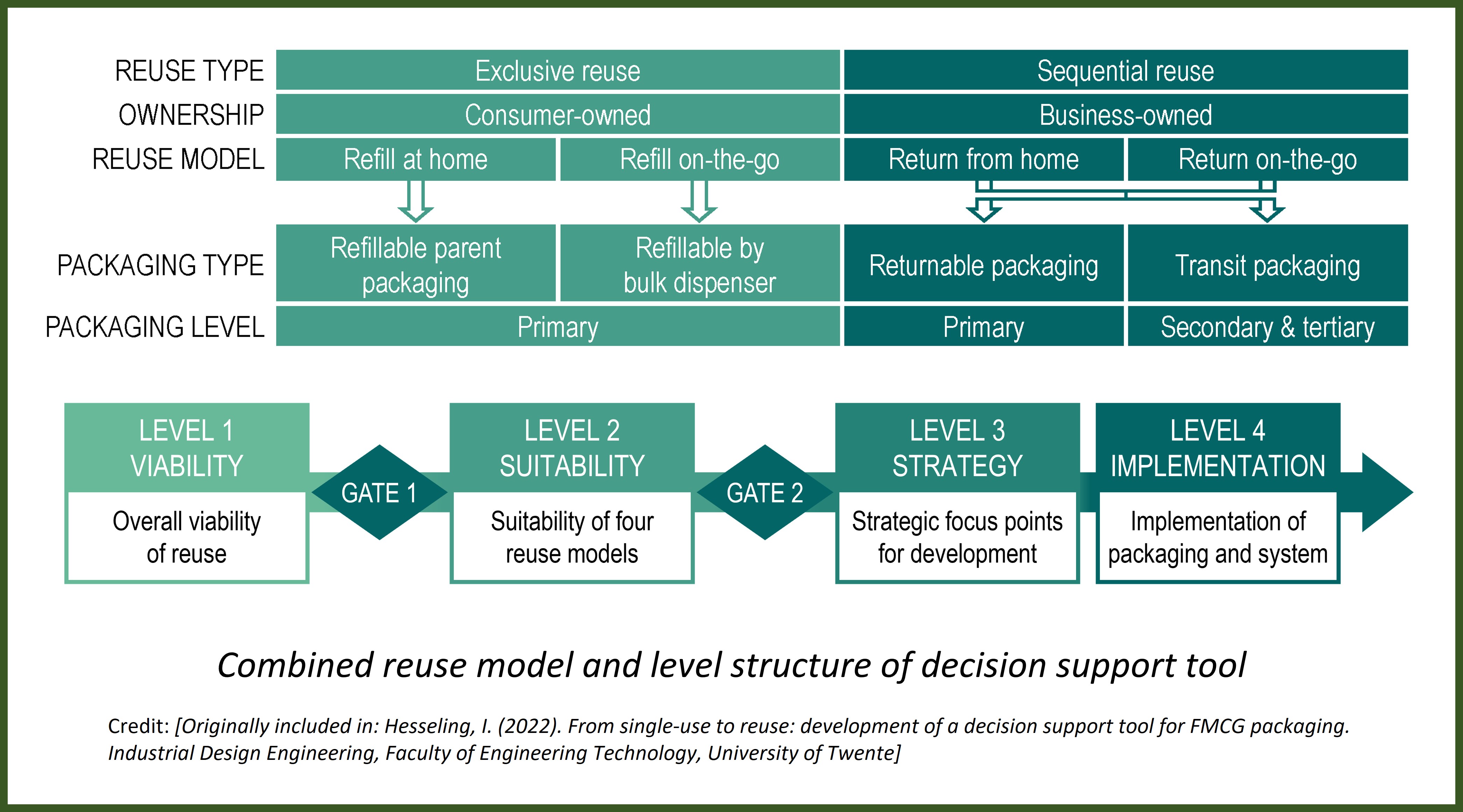

| Fresh approaches to sustainability When it comes to interpretations of ‘sustainability’ relating to packaging, a glance at the list of IAPRI Conference papers this year and in previous years shows a primary focus on bio-based (including biodegradable) materials. Among brands and consumers, on the other hand – and some researchers - the emphasis has fallen on mechanical recycling and recyclability. Others are exploring less familiar approaches. It is understandable that an industry which has for decades taken volume and value growth as its paradigm should be dragging its feet when it comes to anything pulling in the opposite direction – including the promotion of reusable packaging. But researchers at the University of Twente in the Netherlands are among those helping to make reuse a key component in the sustainable packaging mix. Multi-trip or single-use? At the 2022 IAPRI Conference, Twente offered presentations on a number of themes, including tools to aid designers and brand-owners in their packaging decision-making. One of these looked at the creation of a ‘tool pack’ to provide access to the latest insights into consumers’ sustainable behaviour, in the specific context of food and drink. A second was on the development and validation of a tool for reusable packaging design.  The reusables decision support tool uses a four-level stage-gate approach (see diagram). One of the primary issues this strategy addresses is the need to factor in a wide range of stakeholders and criteria. “[It] helps in balancing stakeholder values in relation to reusable packaging – for example, the role of marketers in relation to other influencing stakeholders – going beyond the current theoretical reusable packaging classifications,” the paper explains. The reusables decision support tool uses a four-level stage-gate approach (see diagram). One of the primary issues this strategy addresses is the need to factor in a wide range of stakeholders and criteria. “[It] helps in balancing stakeholder values in relation to reusable packaging – for example, the role of marketers in relation to other influencing stakeholders – going beyond the current theoretical reusable packaging classifications,” the paper explains.Co-author of both papers, Twente’s Bjorn de Koeijer says that these research concerns have evolved in the interim, though still with sustainability as a constant priority. “Reusability remains a key area for us,” he tells IAPRI. “But we’re looking at the added value of imagining the supermarket of the future and the new ways in which retail could develop. Two students will submit an abstract for next year’s Conference, diving into retail systems for the future.” There is a focus on bricks-and-mortar retail, including refills and “the whole returns journey”, he says. “But in our Virtual Reality lab, and through use of Augmented Reality, we’re imagining going beyond bricks-and-mortar to look at online retail, and how packaging design could be very different in that context,” de Koeijer reports. Of course, single-trip-versus-multi-trip debates do not only apply to primary packaging. At California’s Cal Poly, Joongmin Shin and Jay Singh prepared a paper for the last Conference comparing the environmental impact of single-use and multi-use pallets in a range of materials. Surprisingly, perhaps, lifecycle analysis (LCA) here favoured plastics pallets – HDPE and specifically EPS composite – over corrugated board, aluminium, and wood. “The packaging-specific indicators used were packaging-to-product ratio and packaging-to-landfill or recycled,” said the abstract. “The EPS composite pallet, weighing 3.4kg, was the lightest of all pallet types and had a packaging-to-product ratio of approximately 1.3%. Using the assumption of 20% of all pallet systems ending up in landfill, the EPS composite pallet, at 0.33kg, also outperformed all others.” Converting carbon dioxide If there were awards for the names – rather than simply the outcomes – of research projects, then Finland’s Forest CUMP would probably deserve one. Unsurprisingly, the project has absolutely nothing to do with the Tom Hanks film, and everything to do with the forestry industry, plus Carbon Utilization for Materials and Plastics. As VTT research professor Juha Lehtonen tells IAPRI, this project builds on another – BECCU – which ran from 2020 to mid-2022 and explored CO2 capture and conversion to produce polyurethane, for use in areas such as insulation and industrial adhesives. Forest CUMP utilizes similar technology, he says, but with the objective of producing polyethylene and polypropylene – the two most common plastics, with many packaging applications. “Forestry industry emissions in Finland amount to around 20 million tonnes of biogenic CO2 a year, which is nearly a half of the country’s total emissions,” Lehtonen tells IAPRI. It might seem a paradox that emissions from the pulp, paper and board supply chain will contribute to plastics production. But as he points out, this industry also uses large amounts of film packaging itself. The new project, which launched in August 2022, is not the only R&D or commercial enterprise to be investigating CO2 capture and conversion, but according to VTT, its technology is more efficient than many in terms of how the gas is utilized. It will be captured from waste-to-energy as well as pulp and paper plants, says Lehtonen. Technologies have already been developed, and will be further improved, from refining to multi-stage synthesis in conjunction with hydrogen. “We have adapted the process at lab-scale to the production of polyolefins,” he explains. “The end-point will be to demonstrate how this technology works on a real industrial site, including the electrolytic production of hydrogen from water, and to be able to ship the monomer to [project partner] Borealis.” VTT talks about having a small test plant in an industrial environment up and running during 2024. But an industrial-scale plant may not come onstream until 2029 or 2030, Lehtonen admits. “The main challenge is to make the process profitable,” he says. “This is to do with the efficiency of the system, and optimising the capture, as well as the downstream processes.” The project is funded by Business Finland, and is part of its Veturi ecosystem. Commercial partners include Borealis and Neste, along with major forestry groups such as Metsä Serla and Stora Enso. IAPRI member Lappeenranta University of Technology (LUT) is also involved, specifically looking at the carbon capture and purification side of the operation. Recycling reimagined VTT is among those also researching chemical recycling (along with mechanical recycling) of plastics. According to Lehtonen, most of this research effort has been directed towards pyrolysis, in VTT’s case. For the majority of independent research teams, the entry-level requirements in terms of expertise and infrastructure when it comes to many of the chemical recycling technologies may simply be too high. Up until now, there have also been question marks hanging over the sustainability or otherwise of these systems, whether on the basis of their energy requirements, output products – or the potential impact on mechanical recycling. Meanwhile, those pushing to do more with mechanical recycling have been exploring ways to refine the identification and sorting process for post-consumer recycled (PCR) plastics to take it beyond the rudimentary levels associated with near-infrared (NIR). Prominent here have been the Holy Grail projects which, with the involvement of some major international brand-owners, propose the use of ‘digital watermarks’ to allow sorting on the basis of food/non-food grade, colour, and so on – as well as basic polymer type. In a further University of Twente paper for the 2022 Conference, IAPRI President Roland ten Klooster teamed up with Ulphard Thoden van Velzen of the University of Wageningen, also in the Netherlands, to examine an alternative method of differentiating food-grade PCR from non-food-grade material. The 3D dots of the CurvCode can be identified at high line speeds, says the paper, using a combination of lighting, RGB cameras and custom-designed software. Trials were carried out with PP and PET packaging. “The sorting yield was over 90%, with no false positives, showing that 3D relief dots can be used for this purpose,” it said. Thermoformed as well as injection moulded packaging was trialled, with finer control required over the former process to ensure that the codes were consistently readable. Mechanical recycling of plastics, design-for-recycling and recycled content are all likely to grow in importance over the next few years, but so, too, are complementary elements which can help to make sustainability a reality. Although the rules are shifting around the globe, Europe’s regulators appear to be setting the pace. “From the Single Use Plastics directive to the new Packaging and Packaging Waste directive, legislation is becoming more rigid,” says de Koeijer. “Over the coming years, the leading brands will have to go through some major transitions. It’s going to be an interesting decade for sustainability.” Published: 12/23/22 |