News Items - International Association of Packaging Research Institutes

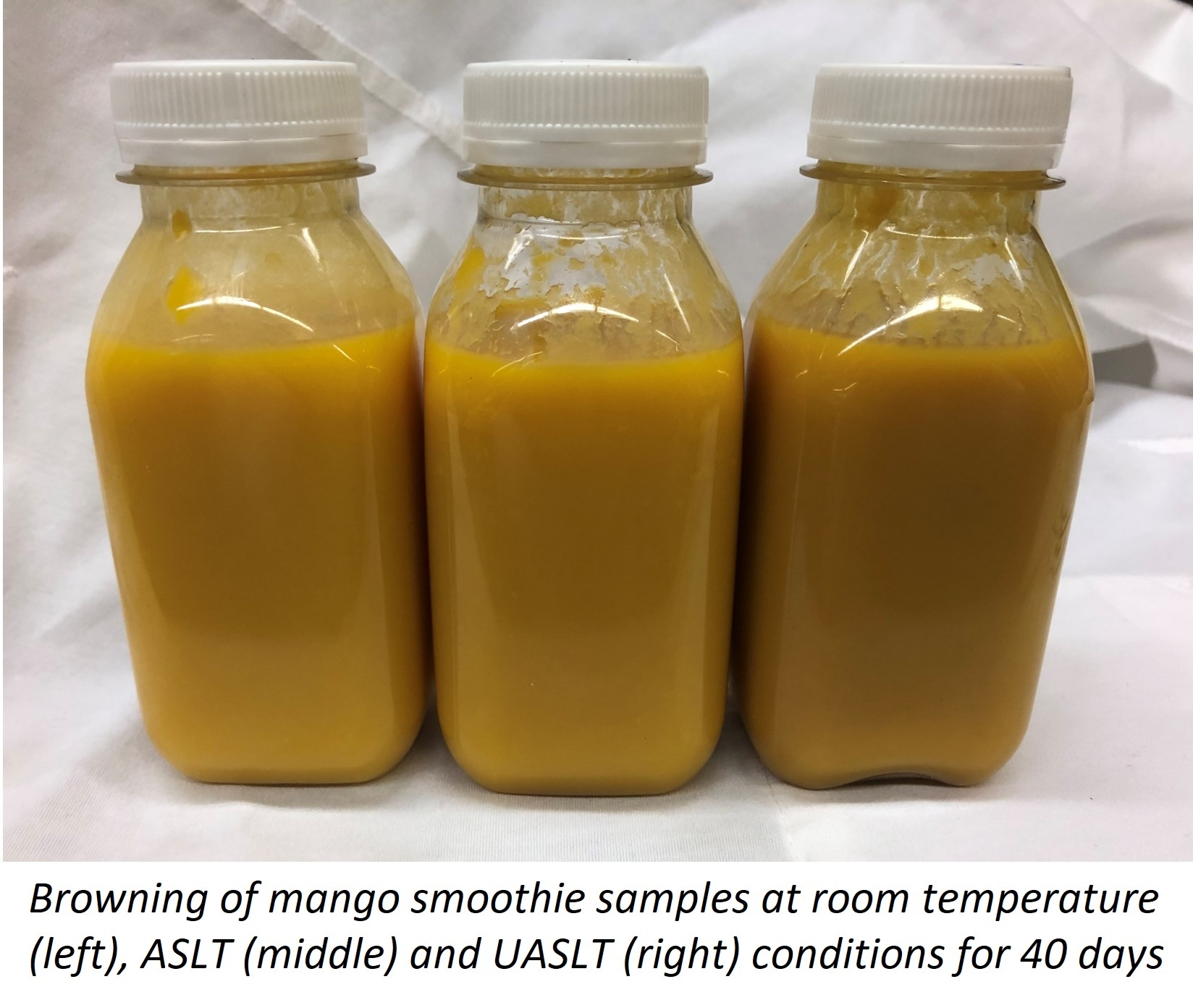

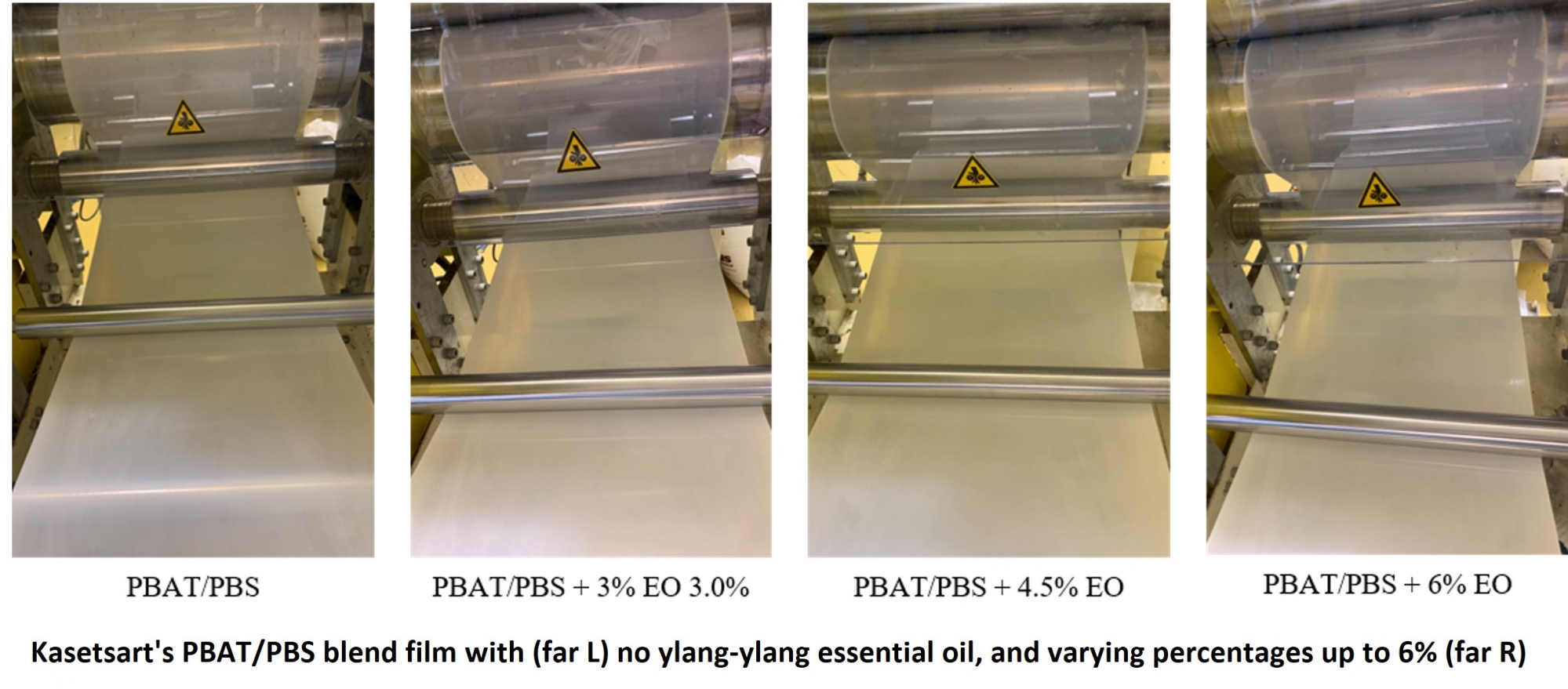

| A long look at short shelf-life After last month’s broad keynote overview of trends in food and drink, we turn to research papers from the June IAPRI Conference examining shelf-life and materials testing for particular product supply chains It is easy to assume that logistics systems for fresh produce the world over are gradually becoming more sophisticated, rather that the opposite, and moving – for instance – towards the greater use of chill chains to protect product quality and shelf-life. Keeping a cool head  But in fact, as the team at Japan’s National Agriculture and Food Research Organization (NARO) points out, growers and processors of crops such as fresh broccoli are often facing a reduced availability of refrigerated trucks and of drivers to transport these loads. Increasingly, too, retailers and their partners are eager to find lower-energy, lower-carbon options. But in fact, as the team at Japan’s National Agriculture and Food Research Organization (NARO) points out, growers and processors of crops such as fresh broccoli are often facing a reduced availability of refrigerated trucks and of drivers to transport these loads. Increasingly, too, retailers and their partners are eager to find lower-energy, lower-carbon options.NARO investigated a high-performance thermal insulation box which can be used for fresh vegetables, once the produce has been pre-cooled. Since the temperature of the box inside the ambient truck gradually increases, researchers wanted to plot quality changes against time and temperature. Tests were run at 2degC and then at 5-degree intervals between 5degC and 20degC, with 85-90% relative humidity over 21 days. Summarising their project, NARO researchers Hiroaki Kitazawa, Naoki Sugino and Takashi Watanabe say: “We propose a mathematical model to predict the change in commercial quality of broccoli under several temperature conditions.” The broccoli heads kept at different temperatures were assessed at intervals of between one and three days and given a score on the basis of wilt, rot and yellowing. Scores spanned the range from 5 (unaffected) to 1 (completely affected). In addition, a holistic assessment was made on the basis of how close overall quality was to the original, and whether it was fit for sale. The research was part-funded by the Japanese business which provided the insulated unit. “Our future research will focus on designing and improving the thermal insulation box by considering actual transportation conditions, such as duration and temperature,” say the authors. They add that they will also explore the effect of harvest season on quality changes in the broccoli. Accelerated testing Depending on the packaged product, there are different techniques available to achieve accelerated shelf-life testing (ASLT), where temperature is typically used to reduce analysis time.  A team including researchers from the Department of Food Science at Purdue University, Indiana, in the US examined ways of moving to an ultra-accelerated shelf-life testing (UASLT) procedure. In this case, pressure was used to accelerate testing further. Mango smoothie containing whey protein and fortified with different vitamins was used as the model food and filled into PET bottles. These were placed in a high-pressure (138kPa) environment in 100% oxygen at 40degC. ASLT control samples were kept at the same temperature but without additional pressure. Changes in colour and vitamin integrity were monitored under both types of conditions. A team including researchers from the Department of Food Science at Purdue University, Indiana, in the US examined ways of moving to an ultra-accelerated shelf-life testing (UASLT) procedure. In this case, pressure was used to accelerate testing further. Mango smoothie containing whey protein and fortified with different vitamins was used as the model food and filled into PET bottles. These were placed in a high-pressure (138kPa) environment in 100% oxygen at 40degC. ASLT control samples were kept at the same temperature but without additional pressure. Changes in colour and vitamin integrity were monitored under both types of conditions.In the ASLT samples, degradation was initially driven by the headspace and dissolved oxygen, but once these sources were depleted, elevated temperature played the lead role. In the UASLT samples, degradation was driven by the constant supply of oxygen, thanks to the elevated pressure, as well as temperature. The ASLT and UASLT conditions were maintained for 40 days. According to the paper’s conclusions: “The food sample experienced a realistic aging process, since the oxygen level inside the packaging was maintained below <0.21kPa [atmospheric level], and only moderate temperature of 40degC was used.” The study results indicate that elevated external oxygen pressure can be used to accelerate tests, along with temperatures in this range, the authors add. Tailored and sustainable While in the case of the broccoli and the smoothie, the focus is on the quality of the fresh product over time, other Conference papers took material innovation as their main concern. This was especially the case where renewable and biobased materials are tailored with natural additives to enhance their performance and characteristics. Research carried out by Thailand’s Kasetsart University experimented with thermoplastic starch (TPS) and polybutylene adipate-co-terephthalate (PBAT). In one paper, these bioplastics were blended with phosphate compounds to ascertain how these affected the mechanical, barrier and morphological properties of TPS/PBAT blown films. Scanning electron microscopy suggested that one of the two phosphate compounds trialled modified the microstructure of the blend to make it more homogenous. Both compounds modified thermal stability and barrier properties. When used to package processed meats, both phosphate additives helped to prolong the shelf-life of the products. Different kinds of active compounds featured in a second paper presented by Kasetsart researchers. Once again, PBAT was used, but this time blended with polybutylene succinate (PBS) and with ylang-ylang essential oil as the active packaging ingredient. The manufacturing technique used was single-screw cast extrusion. “The essential oil improved the compatibility of the PBAT/PBS films, enhancing the smooth surface and reducing phase separation,” explains Kasetsart’s Nathdanai Harnkarnsujarit. “It acted as a compatibilizer and plasticizer, leading to modified mechanical properties.” When the active film was trialled as packaging for two traditional Thai starch-based desserts, Pandanus pudding and Thai layer desserts, results were equally impressive, according to Kasetsart, clearly delaying microbial growth in these products. Specifically, the control samples packaged in film without essential oil additive showed evidence of microbial growth after 10 days for the layer dessert and 18 days for the pudding. “The PBAT/PBS films incorporating ylang-ylang essential oil effectively delayed microbial growth and extended shelf-life of the Thai desserts for five and four days, respectively, in the Pandanus pudding and Thai layer dessert,” says Harnkarnsujarit. Properties of the film which were investigated include microstructure, mechanical properties, water vapour permeability (WVP) and oxygen transmission rate (OTR). When the essential oil was added in different concentrations (from 0% to 6%), it was noted that the roughest and most layered surface was on the PBAT/PBS film with no ylang-ylang additive. As well as improving compatibility between the polymers and smoothing the film surface, addition of the essential oil increased mechanical strength and flexibility in the film. OTR was also increased. On the other hand, the ylang-ylang had barely any effect on WVP. Metal oxide addition  Finally, returning to the blended combination of PBAT and TPS (in this case, cassava starch), the Kasetsart researchers carried out a separate project to investigate the effects of adding three different metal oxides to the material: titanium oxide (TiO2), zinc oxide (ZnO) and silicon oxide (Si02). Finally, returning to the blended combination of PBAT and TPS (in this case, cassava starch), the Kasetsart researchers carried out a separate project to investigate the effects of adding three different metal oxides to the material: titanium oxide (TiO2), zinc oxide (ZnO) and silicon oxide (Si02).Produced through blown film extrusion, the material’s microstructure was analysed using scanning electron microscopy (SEM) and atomic force microscopy (AFM). As in the previous project, incompatibility between the two polymers led to the creation of micro-pores in the structure. “Films containing TiO2 and SiO2 showed increasing tensile strength, due to the good dispersion of nanoparticles across the polymer matrices, while agglomeration of ZnO gave the opposite result,” Harnkarnsujarit reports. The TiO2 oxide was the only one of the three to bring down WVP. The evenness with which each oxide dispersed throughout the polymer matrix was critical in determining resulting film properties. “Agglomeration of the particles decreased the mechanical properties and created defects which increased the permeability of the films,” he explains. Tests also checked specific migration of the metal oxides into three simulants: distilled water, an ethanol solution and acetic acid solution. High levels of metal release, says Kasetsart, were mainly due to the solubility of the TPS polymer, causing swelling in the material, deformation and the release of metals into the simulant. Published: 08/29/22 |